MIT Researchers Develop Innovative Technique for Integrating 2D Materials into Devices

New method allows for the seamless integration of 2D materials into electronic devices, unlocking their unique properties and potential.

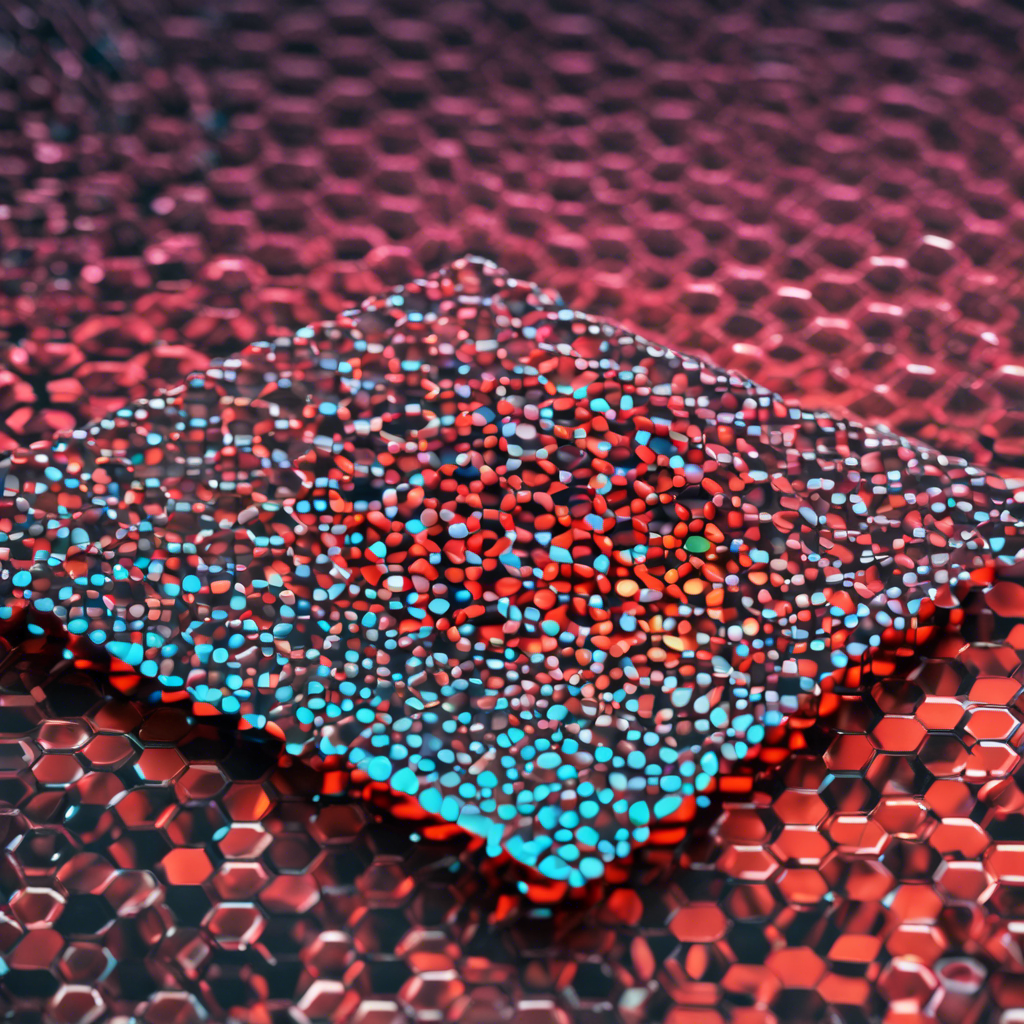

Two-dimensional (2D) materials have been hailed for their remarkable properties, such as efficient electric charge transport, which could revolutionize the performance of next-generation electronic devices. However, integrating these ultrathin materials into devices has proven to be a formidable challenge due to their susceptibility to damage during conventional fabrication processes. In a groundbreaking development, researchers from MIT and other institutions have devised a novel technique that enables the integration of 2D materials into devices in a single step, while preserving their pristine surfaces and interfaces. This breakthrough could pave the way for the widespread application of 2D materials in high-performance computing, sensing, and flexible electronics.

Harnessing the Power of Van der Waals Forces

The key to the researchers’ success lies in harnessing the power of van der Waals forces, which are natural forces of attraction that exist between all matter. Van der Waals forces allow for the physical stacking of 2D materials onto prebuilt device layers, without causing damage to the materials. By utilizing these forces, the researchers can fully exploit the unique optical and electrical properties of 2D materials.

Overcoming the Limitations of Van der Waals Integration

While van der Waals forces are advantageous for integrating materials, they have inherent limitations. The forces are dependent on the intrinsic properties of the materials and cannot be easily tuned. This poses a challenge when trying to integrate certain materials using van der Waals interactions alone. To overcome this limitation, the researchers developed a platform that enhances the versatility of van der Waals integration, enabling the creation of 2D-materials-based devices with new and improved functionalities.

A Single-Step Integration Process

Traditionally, the integration of 2D materials into devices required the use of sacrificial layers or intermediate materials. However, the MIT researchers have devised a single-step process that eliminates the need for these additional layers. They embed a low-adhesion insulator in a high-adhesion matrix, which allows the 2D material to adhere to the insulator surface through van der Waals forces. This approach ensures a clean interface between the 2D material and the insulator, maximizing the material’s performance without the limitations imposed by defects or contamination.

Advancing Device Functionality

The researchers successfully applied their technique to fabricate arrays of 2D transistors, demonstrating new functionalities compared to devices fabricated using conventional methods. The clean interface and pristine surfaces enabled the researchers to engineer the 2D material’s surface and create connections to other components, expanding the possibilities for device design and performance. For example, the team achieved the creation of p-type transistors, which are typically challenging to make with 2D materials, and improved upon previous studies in this area.

Scaling Up and Expanding Possibilities

The single-step integration process developed by the MIT researchers can be scaled up to produce larger arrays of devices. Moreover, the adhesive matrix technique can be applied to a wide range of materials and can even be combined with other forces to enhance the versatility of the platform. In one experiment, the researchers successfully integrated graphene onto a device using a matrix made with a polymer, relying on chemical interactions rather than van der Waals forces alone. This highlights the potential for further exploration and the integration of diverse 2D materials to study their intrinsic properties and develop new device platforms.

Conclusion:

The MIT researchers’ innovative technique for integrating 2D materials into devices represents a significant breakthrough in the field of materials science. By leveraging the power of van der Waals forces and eliminating the need for sacrificial layers, the researchers have overcome the limitations of conventional fabrication techniques. This advancement opens up new possibilities for the widespread application of 2D materials in various fields, including high-performance computing, sensing, and flexible electronics. As the research continues, the platform developed by the MIT team holds the potential to unlock the full potential of 2D materials and pave the way for the development of next-generation electronic devices.