Armoring Metal Alloys with Hexagonal Boron Nitride Coatings for Enhanced Performance

Researchers Discover Non-Stick and Corrosion-Resistant Qualities in hBN-Coated Metal Alloys

Metal alloys have long been valued for their strength, durability, and resistance to corrosion and oxidation. However, scientists are constantly seeking ways to further enhance these materials to meet the demands of various industries. In a groundbreaking study published in Advanced Materials Interfaces, researchers have demonstrated the remarkable potential of hexagonal boron nitride (hBN) coatings in improving the performance of metal alloys. These coatings not only provide non-stick and low-friction qualities but also offer long-term protection against harsh corrosion and high-temperature oxidation in air. The findings open up exciting possibilities for a wide range of applications, from solar panels and semiconductors to aerospace turbine blades.

The Power of Armoring Metal Alloys

Metal alloys play a crucial role in numerous industries, from manufacturing to aerospace. Their inherent strength and resistance to corrosion and oxidation make them ideal for a wide range of applications. However, by adding protective coatings, scientists can further enhance the capabilities of these alloys. The concept of “armoring” metal alloys involves applying a layer of material that enhances their durability, heat resistance, and resistance to wear and friction. This process has the potential to revolutionize existing products and pave the way for the development of innovative new ones.

The Versatility of hBN Coatings

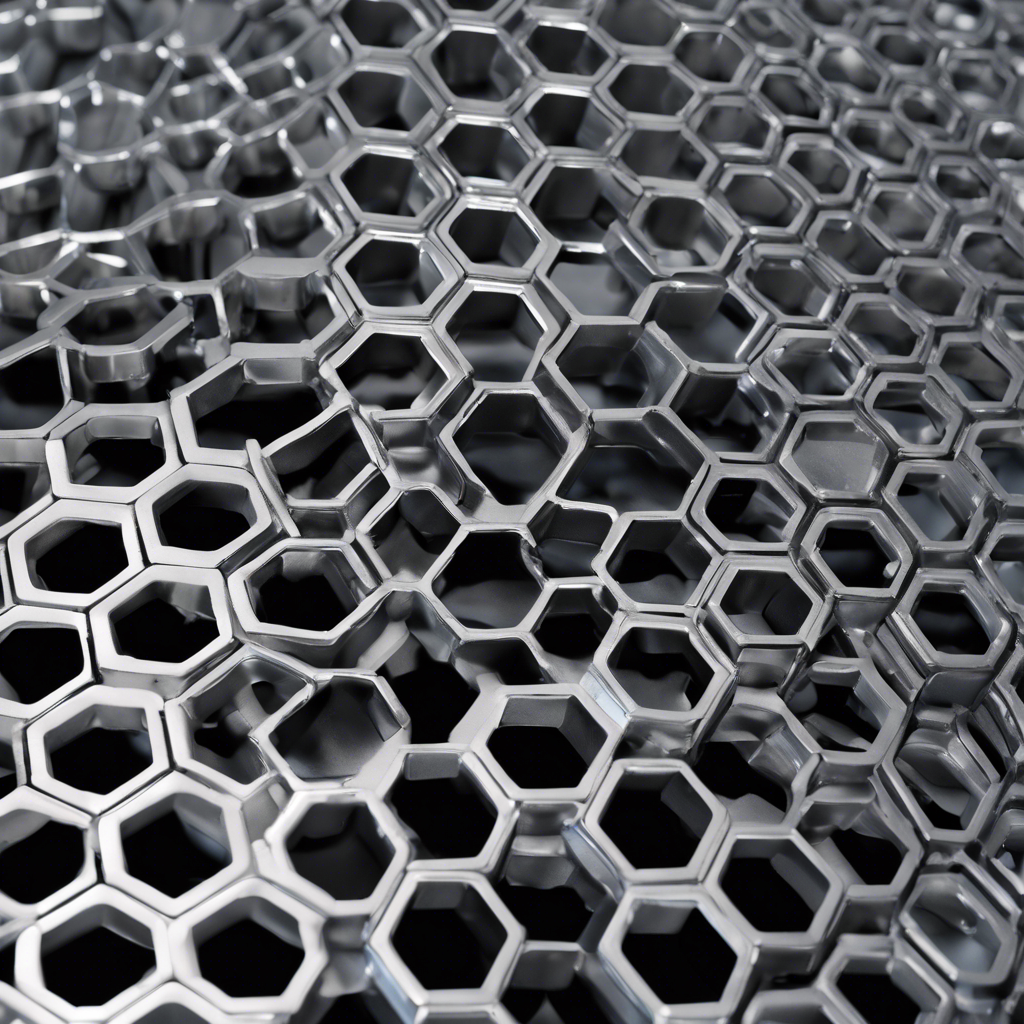

In the quest to find the most effective coating material, researchers turned their attention to hexagonal boron nitride (hBN). This material, composed of boron and nitrogen atoms arranged in a hexagonal lattice structure, exhibits remarkable properties that make it an ideal candidate for armoring metal alloys. The hBN coatings can be produced through a process called atmospheric pressure chemical vapor deposition, which combines solid boron sources and molecular nitrogen. This technique ensures scalability, cost-effectiveness, and process safety, addressing previous challenges associated with coating applications.

Non-Stick and Low-Friction Qualities

One of the key advantages of hBN-coated metal alloys is their non-stick and low-friction qualities. The hBN coating creates a surface that is resistant to adhesion, preventing the buildup of contaminants or debris. This property is particularly valuable in applications such as solar panels, where the accumulation of dust or dirt can significantly reduce efficiency. By reducing friction, hBN coatings also enhance the performance of semiconductors, allowing them to maintain optimal operating temperatures and prevent overheating.

Protection Against Corrosion and Oxidation

Metal alloys are susceptible to corrosion and oxidation when exposed to harsh environmental conditions. However, the hBN coatings provide a robust barrier that protects the underlying metal from these detrimental processes. The corrosion resistance of hBN-coated metal alloys makes them ideal for applications in marine environments, where exposure to saltwater can cause rapid deterioration. Furthermore, the coatings exhibit excellent resistance to high-temperature oxidation, making them suitable for use in aerospace turbine blades that operate under extreme heat conditions.

Potential for Two-Dimensional Electronic and Photonic Devices

In addition to their applications in armoring metal alloys, hBN coatings hold promise for emerging two-dimensional electronic and photonic devices. The ability to synthesize single- and few-layer hBN using the atmospheric pressure chemical vapor deposition process opens up new possibilities for improving the performance of these devices. With their unique properties, hBN coatings could enhance the functionality and longevity of electronic components, leading to advancements in fields such as telecommunications, optoelectronics, and quantum computing.

Conclusion:

The discovery of the non-stick, low-friction, corrosion-resistant, and high-temperature oxidation properties of hBN-coated metal alloys represents a significant breakthrough in materials science. The potential applications of these coatings are vast, ranging from solar panels and semiconductors to aerospace turbine blades. The scalability and cost-effectiveness of the atmospheric pressure chemical vapor deposition process make hBN coatings an attractive option for industries seeking to enhance the performance and durability of their products. As research in this field continues to advance, we can expect to see the widespread adoption of hBN coatings, ushering in a new era of enhanced materials and technologies.