Breakthrough in Miniaturization: Scientists Develop Micrometric Photovoltaic Cells

University of Ottawa researchers achieve a milestone in miniaturization with the creation of back-contact micrometric photovoltaic cells.

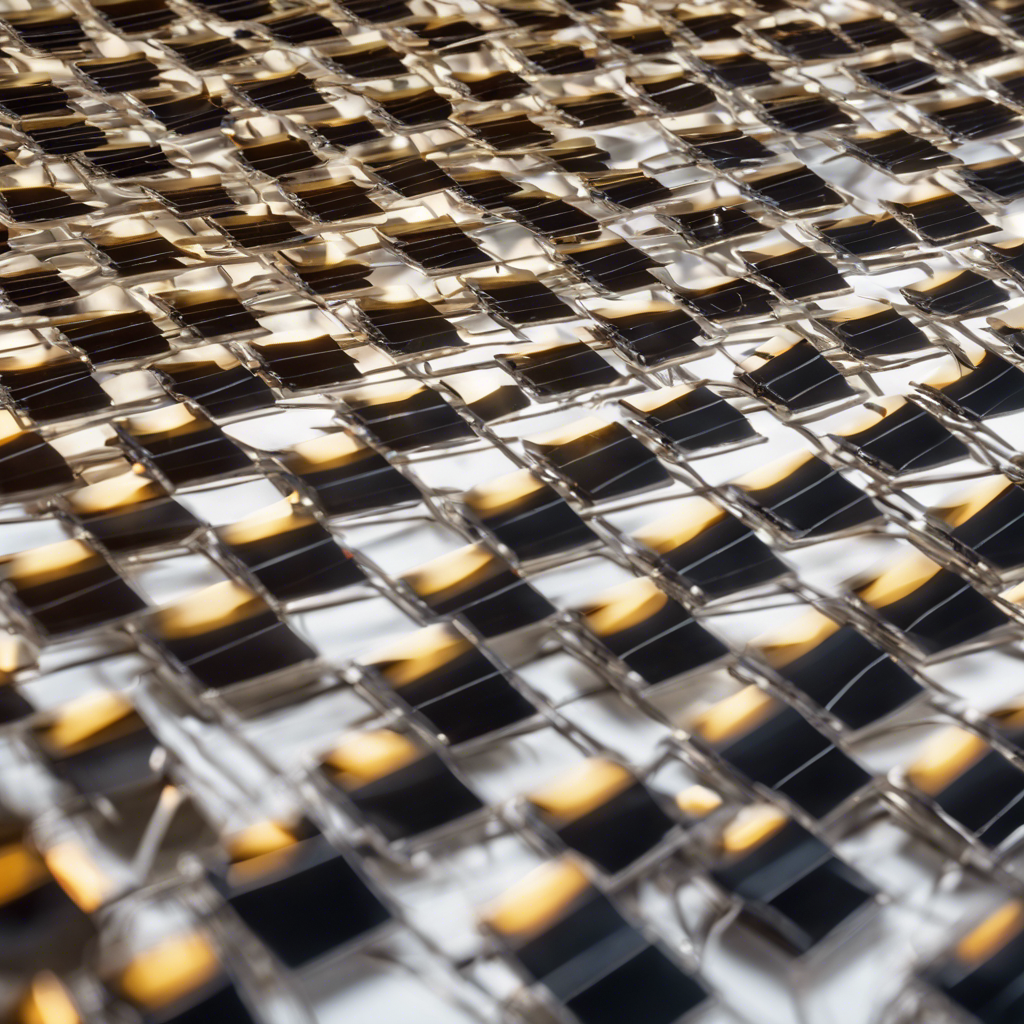

The quest for more powerful solar cells and miniaturized electronics has been a topic of intense research worldwide. Now, scientists at the University of Ottawa have made a groundbreaking discovery that could revolutionize the field of electronic devices. Mathieu de Lafontaine, a postdoctoral researcher, and Karin Hinzer, vice-dean of research, have successfully manufactured the first back-contact micrometric photovoltaic cells. These cells, with a size twice the thickness of a strand of hair, offer significant advantages over conventional solar technologies, reducing electrode-induced shadowing by 95% and potentially lowering energy production costs by up to three times. This breakthrough has been achieved through a research partnership between the University of Ottawa, the Université de Sherbrooke, and the Laboratoire des Technologies de la Microélectronique in Grenoble, France.

Advantages of Micrometric Photovoltaic Cells

The newly developed micrometric photovoltaic cells possess remarkable characteristics, including an extremely small size and significantly reduced shadowing. These properties make them suitable for various applications, such as densification of electronic devices, more efficient solar cells, lightweight nuclear batteries for space exploration, and miniaturization of devices for telecommunications and the internet of things. The potential impact of these cells on society is enormous, as they promise less expensive and more powerful solar cells, facilitate space exploration through lightweight nuclear batteries, and contribute to the growth of the internet of things by enabling the miniaturization of devices.

Miniature Solar Cells Explained

In a research paper published in the journal Cell Reports Physical Science, the scientists explain the process behind the creation of these miniature solar cells. They highlight the use of three-dimensional (3D) interconnects to increase chip power density and enable miniaturization. The fabrication of these interconnects involves processes such as III-V heterostructure plasma etching, gold electrodeposition, and chemical-mechanical polishing to integrate through substrate vias to the heterostructure. The researchers demonstrate the use of these interconnects in photonic power devices that have areas three orders of magnitude smaller compared to standard chips. The design also reduces shading factors to below 3% and achieves a 6-fold increase in wafer area use compared to miniaturized photonic power devices with two-dimensional connections. These advancements open up possibilities for power over fiber, the internet of things, and microconcentrator photovoltaics.

The Road to Commercial Production

While the breakthrough is significant, the researchers acknowledge the challenges of transitioning from the lab to commercial production. They identify three main challenges associated with the enhanced level of complexity in a 3D architecture: increased failure risks, increased manufacturing costs, and the requirement for specialized tools. The researchers propose that the knowledge and techniques already established in the CMOS industry can mitigate the risks associated with failure and help reduce manufacturing costs. They also note that specialized tools not commonly used in the multijunction photovoltaic industry will be required for manufacturing these miniature solar cells. However, they highlight that techniques such as plasma etching, atomic layer deposition, and chemical-mechanical planarization have been well-known and used in the CMOS industry for several decades, suggesting the relevance of this industry in manufacturing these devices.

The Implications of Miniaturization

The development of back-contact micrometric photovoltaic cells represents a crucial step in the miniaturization of electronic devices. The reduction in shading from electrical connections allows for even greater miniaturization of silicon-based electronic components. This breakthrough has the potential to revolutionize various industries, including electronics, telecommunications, and space exploration. The cost reduction and increased power yield per wafer associated with these miniature solar cells could accelerate the energy shift, facilitate space exploration through lightweight nuclear batteries, and lead to more powerful computers and smartphones. While concerns about the necessity of smaller, more powerful electronics exist, basic research projects like this focus on pushing the limits of what is possible, leaving the commercial viability and societal benefits to be determined by others.

Conclusion:

The University of Ottawa researchers’ achievement in manufacturing back-contact micrometric photovoltaic cells marks a significant milestone in the field of miniaturization. These cells offer advantages such as reduced shadowing and the potential for lower energy production costs. The breakthrough opens up possibilities for various applications, from more efficient solar cells to lightweight nuclear batteries for space exploration and miniaturized devices for telecommunications and the internet of things. While challenges remain in commercial production, the knowledge and techniques from the CMOS industry can help mitigate risks and reduce manufacturing costs. The implications of miniaturization are vast, with the potential for accelerating the energy shift, advancing space exploration, and enhancing the power of electronic devices. As researchers continue to push the boundaries of what is possible, the future of miniaturization looks promising.